E-textiles, or electronic textiles, are innovative materials that incorporate electronic components—such as sensors, batteries, lights, and microcontrollers—directly into the fabric. This integration allows the fabric to sense, compute, display, or communicate. The selection of fabric for e-textiles is crucial, as it must harmonize traditional textile properties like flexibility, comfort, and durability with the needs of electronic integration. This balance ensures that e-textiles can function effectively while maintaining the desirable characteristics of conventional fabrics.

#1

• Cotton, polyester, and nylon are frequently used as base fabrics due to their flexibility, comfort, and widespread availability.

• These fabrics can be combined with conductive fibers or threads to enable electronic functions.

2. Specialized and Sustainable Fabrics

• Tencel, a biodegradable textile made from wood pulp, is gaining attention for sustainable e-textile applications. It serves as a base fabric that is both comfortable and environmentally friendly.

• Other eco-friendly options are being explored to address the challenges of recycling e-textiles, especially those that use metals like silver, which do not biodegrade easily.

3. Conductive and Functional Fibers

• Conductive threads or yarns are essential for electrical connectivity within the textile. These are typically made by:

o Coating traditional fibers (like cotton or nylon) with metals such as silver or copper.

o Spinning together fibers with metal strands (e.g., stainless steel or silver-plated fibers).

• Advanced e-textiles may use fibers that inherently possess electronic properties, a field known as fibretronics.

Common Fabric Types Used in E-Textiles

1. Conventional Textile Bases• Cotton, polyester, and nylon are frequently used as base fabrics due to their flexibility, comfort, and widespread availability.

• These fabrics can be combined with conductive fibers or threads to enable electronic functions.

2. Specialized and Sustainable Fabrics

• Tencel, a biodegradable textile made from wood pulp, is gaining attention for sustainable e-textile applications. It serves as a base fabric that is both comfortable and environmentally friendly.

• Other eco-friendly options are being explored to address the challenges of recycling e-textiles, especially those that use metals like silver, which do not biodegrade easily.

3. Conductive and Functional Fibers

• Conductive threads or yarns are essential for electrical connectivity within the textile. These are typically made by:

o Coating traditional fibers (like cotton or nylon) with metals such as silver or copper.

o Spinning together fibers with metal strands (e.g., stainless steel or silver-plated fibers).

• Advanced e-textiles may use fibers that inherently possess electronic properties, a field known as fibretronics.

#2

- Inkjet Printing: Conductive inks (such as graphene or PEDOT:PSS) can be inkjet-printed onto fabrics to create flexible, functional circuits while maintaining the textile's original properties.

- Layered Structures: Some advanced e-textiles use a multi-layer approach, with separate layers for sensing, interfacing, and the base fabric.

Methods of Integration

- Embroidery and Weaving: Conductive threads can be embroidered or woven directly into the fabric, allowing for precise placement of electronic pathways and components.- Inkjet Printing: Conductive inks (such as graphene or PEDOT:PSS) can be inkjet-printed onto fabrics to create flexible, functional circuits while maintaining the textile's original properties.

- Layered Structures: Some advanced e-textiles use a multi-layer approach, with separate layers for sensing, interfacing, and the base fabric.

#3

• Durability: E-textiles must withstand repeated use, washing, and mechanical stress.

• Conductivity: Essential for signal transmission and power delivery, achieved through conductive fibers or printed materials.

• Environmental Sustainability: Increasingly important, with research focusing on biodegradable and recyclable materials.

Key Properties Required

• Flexibility and Comfort: The fabric should retain its textile-like feel and be comfortable for wearables.• Durability: E-textiles must withstand repeated use, washing, and mechanical stress.

• Conductivity: Essential for signal transmission and power delivery, achieved through conductive fibers or printed materials.

• Environmental Sustainability: Increasingly important, with research focusing on biodegradable and recyclable materials.

#4

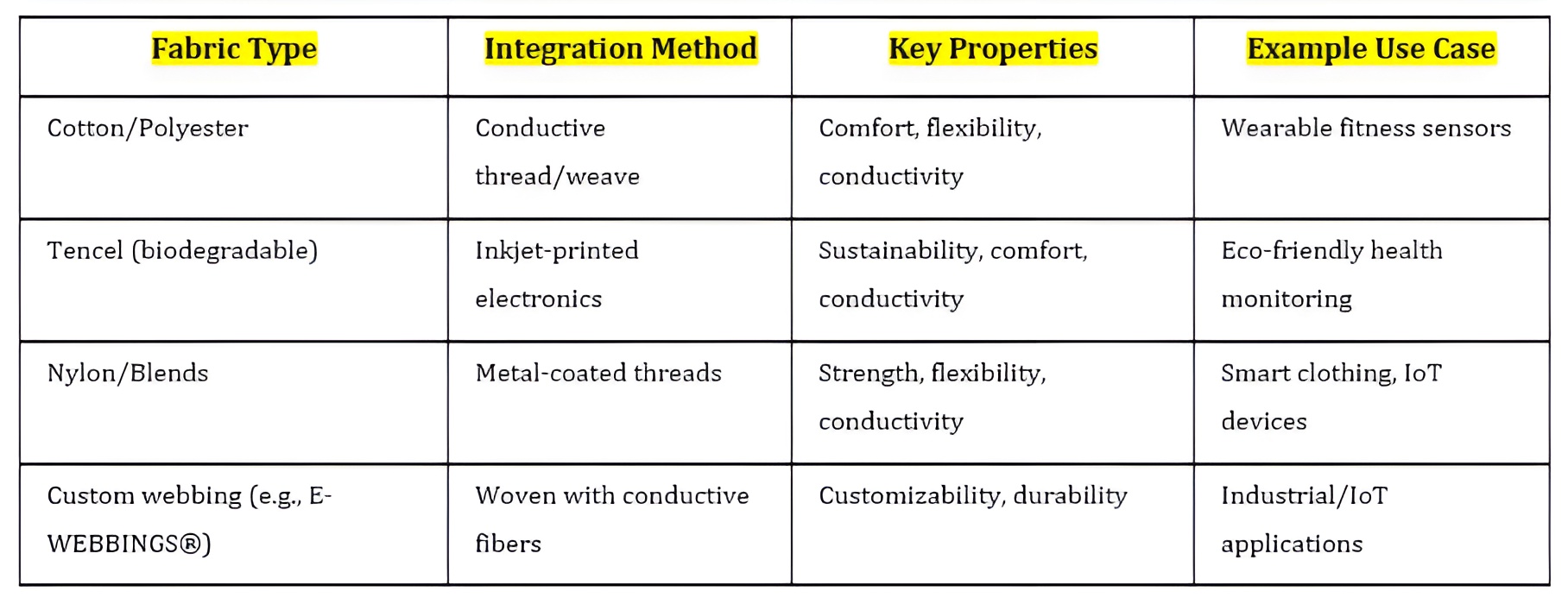

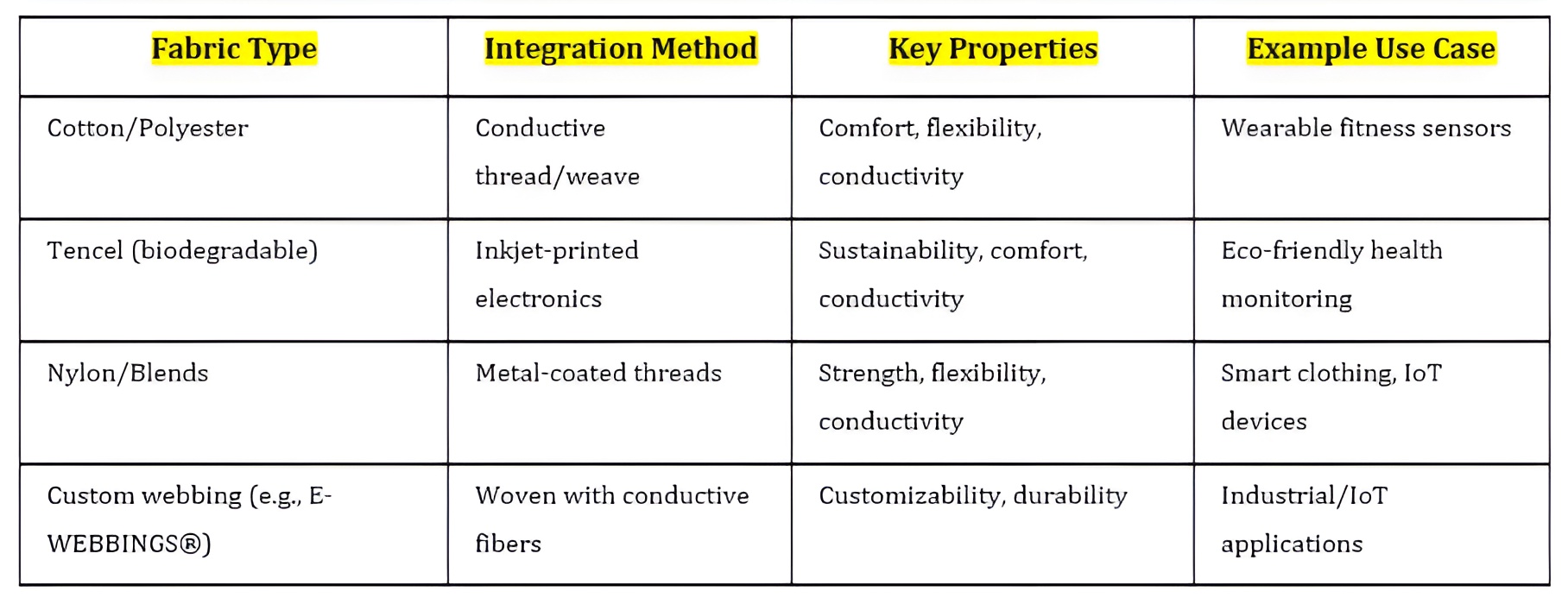

Summary Table: Common Fabrics and Integration Methods

#5

Conclusion

Fabrics for e-textiles range from conventional textiles like cotton and polyester to advanced, sustainable options like Tencel. These are combined with conductive materials through weaving, embroidery, or printing to create functional, flexible, and sometimes biodegradable electronic textiles suitable for a wide range of applications, from smart clothing to environmental sensors.Reactions

Reactions

1